Site de Blog

Linha de Máquinas de Fabricação de Células Cilíndricas Automáticas

fabricação e equipamento de laboratórios de bateria li-ion 18650

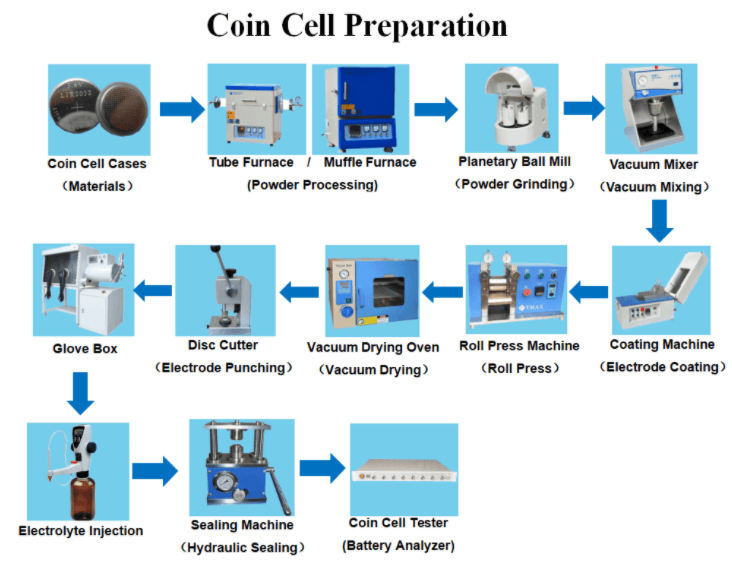

fluxograma de célula de moeda de íon de lítio e lista de máquinas

fabricação e equipamento de laboratórios de baterias com bateria de íon de lítio

dez 2016 aceitação de fábrica do cliente nos EUA da máquina de empilhamento automático

Contate-nos

- Se você tiver dúvidas, entre em contato conosco, todas as perguntas serão respondidas

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Adicionar : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produtos quentes

Coin cell battery test is a rapid method to evaluate the electrical performance of battery materials, which is widely used in the research and development of lithium ion battery cathode materials. The level of button battery manufacturing process is directly related to the reliability of the test results. In order to provide the accuracy of button battery research, we propose the following suggestions.

(a)Materials: All materials especially:NCA electrodes, Celgard separator and LiPF6 electrolytes, —cleanliness of materials is critical.must be stored in a clean, closed environment. These materials should be kept away from the work environment to prevent contamination. Damage caused by accidents or other accidental mishaps on the part of third parties can thus be effectively avoided. This is more important the more sensitive the materials are. Otherwise, the quality of the manufactured cells cannot be guaranteed. Electrodes and separators sometimes vary greatly in their material thicknesses. In test series with different material thicknesses, it should be aimed for a similar overall thickness of the ESC and the coin cell spacers used so the compressive force of the disk coin cell spring on the ESC is the same. Greater material thicknesses in the Celgard separator and electrodes can be compensated for, for example, by using thinner spacers (typical coin cell spacer thicknesses: 0.2, 0.5, 1 mm) or even a different housing type (type R2032, R2025, etc.).

(b)Tools: All tools, such as disc cutting machine, coin cell crimping machine, electrode film coating machine or electrode calender machine ect, should be checked for damage before cell assembly. For example, if the electrode or separator punched by the disc cutting machine has burrs, the performance of the coin cell will be greatly affected. To avoid short circuits, non-conductive tweezers should be used. Furthermore, the tools must be kept in a clean condition throughout the entire manufacturing process. This includes cleaning tools before and after use.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com