Site de Blog

Linha de Máquinas de Fabricação de Células Cilíndricas Automáticas

fabricação e equipamento de laboratórios de bateria li-ion 18650

fluxograma de célula de moeda de íon de lítio e lista de máquinas

fabricação e equipamento de laboratórios de baterias com bateria de íon de lítio

dez 2016 aceitação de fábrica do cliente nos EUA da máquina de empilhamento automático

Contate-nos

- Se você tiver dúvidas, entre em contato conosco, todas as perguntas serão respondidas

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Adicionar : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produtos quentes

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

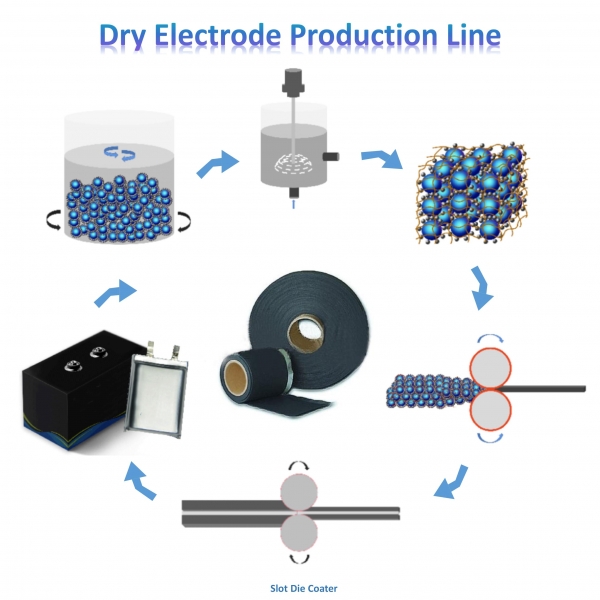

Dry electrode technology represents a transformative approach to the manufacturing of electrodes for energy storage devices, such as lithiumion batteries, solidstate batteries, and supercapacitors. Unlike traditional wetcoating methods that rely on solventbased slurries, dry electrode technology uses dry mixing and compression techniques to create highperformance electrodes without solvents. This innovation not only simplifies the manufacturing process but also significantly reduces environmental impact while enhancing the mechanical properties and performance of electrodes.

In this article, we will explore the principles, advantages, challenges, and future potential of dry electrode technology.

●What Is Dry Electrode Technology?

Dry electrode technology is a method of producing electrodes by combining active materials (e.g., graphite, silicon), binders (e.g., polytetrafluoroethylene [PTFE]), and conductive additives (e.g., carbon black) in powder form. Instead of mixing these components into a liquid slurry, they are blended using dry mixing techniques and then compressed onto a current collector foil (e.g., aluminum or copper) using rollers or laminating systems. The result is a dense, uniform electrode layer with excellent adhesion, mechanical stability, and electrical conductivity.

This solventfree approach eliminates the need for drying ovens and solvent recovery systems, making it more sustainable and costeffective than traditional wetcoating methods.

●Key Principles of Dry Electrode Technology

1. Dry Mixing:

Active materials, binders, and conductive additives are combined in powder form to create a homogeneous mixture.

Highshear mixers or planetary mixers ensure uniform particle distribution.

2. Compression:

The dry powder mixture is compressed onto a current collector foil using rolling or laminating machines.

Controlled pressure and temperature ensure strong adhesion and optimal density.

3. Precision Control:

Realtime monitoring systems measure thickness, density, and uniformity during the production process.

Automated adjustments ensure consistent quality.

4. Scalability:

Modular designs allow for easy scaling to meet mass production demands.

●Advantages of Dry Electrode Technology

1. Environmental Benefits:

Eliminates the use of toxic solvents, reducing emissions and waste.

Reduces energy consumption by avoiding drying and solvent recovery processes.

2. Improved Performance:

Produces electrodes with higher density and better mechanical stability, leading to improved cycle life and performance.

Allows for higher loading of active materials, increasing energy density.

3. Cost Savings:

Simplifies the production process by eliminating solventrelated steps.

Reduces material waste due to precise handling and realtime quality checks.

4. Scalability:

Enables faster production rates compared to traditional wetcoating methods.

Can be easily scaled up for mass production.

5. Flexibility:

Compatible with a wide range of materials, including nextgeneration chemistries like silicon anodes and solidstate electrolytes.

6. Safety:

Minimizes exposure to hazardous chemicals, improving workplace safety.

●Challenges of Dry Electrode Technology

While dry electrode technology offers numerous benefits, it also presents certain challenges:

1. Material Handling:

Ensuring uniform mixing and feeding of dry powders can be complex.

Proper alignment of the powder mixture and current collector foil is critical to avoid defects.

2. Binder Selection:

Developing binders that work effectively in dry conditions while maintaining adhesion and flexibility is challenging.

3. High Initial Costs:

Advanced machinery and specialized components require significant upfront investment.

4. Process Optimization:

Achieving consistent results across largescale production requires finetuning of parameters such as pressure, temperature, and speed.

5. Compatibility with New Materials:

Adapting to emerging electrode materials and cell designs may require frequent upgrades to equipment.

●Innovations in Dry Electrode Technology

To address these challenges and enhance productivity, manufacturers are incorporating cuttingedge technologies:

1. Advanced Mixing Techniques:

Highshear mixers and planetary mixers ensure uniform particle distribution.

2. AI and Machine Learning:

Predictive analytics optimize machine performance, detect anomalies, and improve yield rates.

3. RealTime Monitoring Systems:

Integrated sensors and vision systems provide continuous feedback on thickness, density, and uniformity.

4. Modular Design:

Flexible systems allow for easy reconfiguration to test new materials and chemistries.

5. Sustainability Features:

Ecofriendly practices minimize waste and energy consumption during fabrication.

6. Integration with Automation:

Collaborative robotics and IoTenabled systems enhance efficiency and reduce human intervention.

Dry electrode technology is used in various industries, including:

1. Battery Production:

Produces electrodes for lithiumion batteries, solidstate batteries, and other advanced battery chemistries.

2. Supercapacitors:

Creates highperformance electrodes for energy storage applications in consumer electronics, automotive systems, and renewable energy.

3. Automotive Industry:

Manufactures electrodes for electric vehicle (EV) batteries, focusing on improving energy density and reducing costs.

4. Renewable Energy:

Develops durable electrodes for gridscale energy storage systems.

5. Consumer Electronics:

Produces compact and efficient electrodes for smartphones, wearables, and portable devices.

●The Future of Dry Electrode Technology

As the demand for sustainable and highperformance energy storage solutions grows, dry electrode technology will continue to evolve. Key trends shaping the future include:

1. Increased Automation:

Fully autonomous systems will further boost production speeds and reduce costs.

2. Customization Options:

Modular designs will enable manufacturers to tailor systems for specific materials and cell designs.

3. Focus on Sustainability:

Ecofriendly practices and recycling capabilities will become integral parts of future systems.

4. Integration with Emerging Technologies:

Solidstate batteries, flexible electronics, and autonomous systems will drive new innovations in system design.

5. Smart Manufacturing:

IoTenabled systems will leverage big data and AI to optimize production, reduce waste, and enhance efficiency.

●Conclusion

Dry electrode technology is revolutionizing the energy storage industry by enabling sustainable, efficient, and highperformance electrode fabrication. Its ability to eliminate solvents, reduce waste, and improve mechanical properties makes it a gamechanger for battery and supercapacitor production.

What excites you most about the role of dry electrode technology in driving innovation and sustainability in the energy storage sector? Share your thoughts below! Together, let’s explore how this technology can shape the future of energy storage.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com