Site de Blog

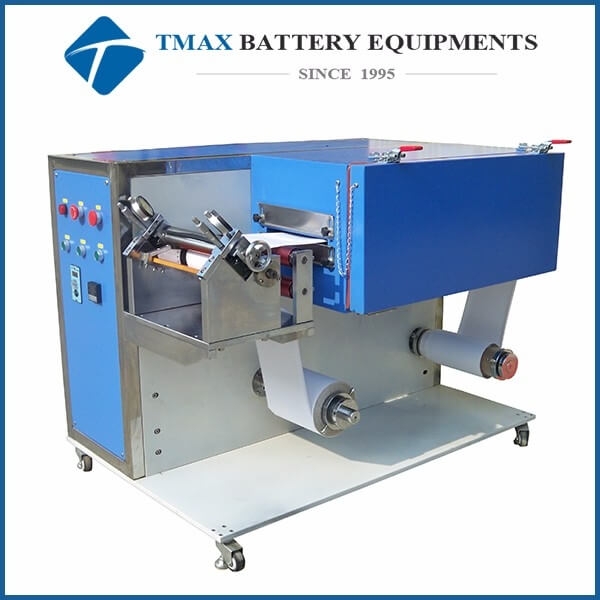

Linha de Máquinas de Fabricação de Células Cilíndricas Automáticas

fabricação e equipamento de laboratórios de bateria li-ion 18650

fluxograma de célula de moeda de íon de lítio e lista de máquinas

fabricação e equipamento de laboratórios de baterias com bateria de íon de lítio

dez 2016 aceitação de fábrica do cliente nos EUA da máquina de empilhamento automático

Contate-nos

- Se você tiver dúvidas, entre em contato conosco, todas as perguntas serão respondidas

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Adicionar : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produtos quentes

Dry coating technology is an emerging method in the battery manufacturing industry, specifically for the production of electrodes in lithium-ion batteries. Unlike traditional wet coating methods that use solvents, dry coating techniques eliminate the need for solvents, leading to numerous advantages such as reduced environmental impact, lower costs, and improved safety. This article provides a detailed overview of the Dry electrode system, its components, functions, advantages, and challenges.

Key Components of a Dry electrode equipment

1.Powder Feeder

Purpose: To supply the active material powders (cathode or anode materials) to the coating system.

Equipment: Vibratory feeders, screw feeders, or pneumatic conveyors.

2.Electrostatic Spraying System

Purpose: To apply the active material powders uniformly onto the current collector.

Equipment: Electrostatic spray guns, powder spray booths, and high-voltage power supplies.

3.Substrate Handling System

Purpose: To transport the current collector (typically aluminum for the cathode and copper for the anode) through the coating process.

Equipment: Roll-to-roll handling systems, tension control mechanisms, and alignment systems.

4.Binder Activation System

Purpose: To activate the binder within the powder mixture, ensuring proper adhesion of the active material to the current collector.

Equipment: Infrared heaters, laser systems, or other thermal activation devices.

5.Calendering Machine

Purpose: To compress the coated electrodes to the desired thickness and density, enhancing electrical conductivity and mechanical integrity.

Equipment: Precision rollers with adjustable pressure settings.

6.Cooling System

Purpose: To cool down the electrodes after the binder activation and calendering processes.

Equipment: Air cooling systems, water cooling systems, or chillers.

7.Dust Collection System

Purpose: To collect any excess powder material that does not adhere to the current collector.

Equipment: Cyclone separators, HEPA filters, and vacuum systems.

8.Control System

Purpose: To monitor and control the entire dry coating process, ensuring consistent quality and performance.

Equipment: Programmable logic controllers (PLCs), human-machine interfaces (HMIs), and sensor networks.

Steps in the Dry Coating Process

1.Powder Preparation

Mixing: Active materials, conductive additives, and binders are mixed to create a uniform powder mixture.

Sieving: The powder mixture is sieved to achieve a consistent particle size distribution.

2.Substrate Handling

Loading: The current collector foil is loaded onto the roll-to-roll handling system.

Tension Control: The foil tension is carefully controlled to ensure smooth transport through the coating machine.

3.Powder Application

Electrostatic Spraying: The powder mixture is sprayed onto the current collector using electrostatic forces to ensure uniform coverage.

Deposition: The charged powder particles adhere to the current collector, forming a loose coating layer.

4.Binder Activation

Thermal Activation: The binder within the powder mixture is activated using heat, causing it to melt and bond the active materials to the current collector.

Solidification: The binder solidifies upon cooling, creating a robust electrode coating.

5.Calendering

Compression: The coated electrode is passed through calendering rollers to achieve the desired thickness and density.

Surface Smoothing: The calendering process also smooths the electrode surface, enhancing contact with the separator.

6.Cooling and Collection

Cooling: The electrode is cooled down to stabilize the coating.

Collection: The coated electrode is collected onto a roll for further processing, such as cutting and assembly.

Advantages of Dry Coating Technology

1.Elimination of Solvents: Reduces environmental impact and eliminates the need for solvent recovery and recycling systems.

2.Cost Reduction: Lowers production costs by removing solvent handling and drying steps.

3.Improved Safety: Minimizes risks associated with flammable and toxic solvents.

4.Higher Throughput: Simplifies the coating process and allows for faster production speeds.

5.Enhanced Material Utilization: Reduces material waste and improves overall efficiency.

Challenges in Dry Coating Technology

1.Powder Handling: Ensuring consistent flow and distribution of the powder mixture can be challenging.

2.Uniformity: Achieving a uniform coating thickness and composition requires precise control of the electrostatic spraying process.

3.Binder Activation: Ensuring complete and consistent binder activation without damaging the active materials.

4.Adhesion: Ensuring strong adhesion of the powder coating to the current collector.

5.Scalability: Scaling up the process for mass production while maintaining quality and consistency.

Development Challenges

1.Material Innovations: Developing new binder and active material formulations that are optimized for dry coating processes.

2.Process Optimization: Refining the electrostatic spraying and binder activation processes to enhance uniformity and adhesion.

3.Equipment Design: Designing and engineering robust, high-precision equipment that can handle the unique requirements of dry coating.

3.Integration: Integrating dry coating technology into existing production lines and ensuring compatibility with other manufacturing processes.

Conclusion

Dry coating technology represents a significant advancement in the production of lithium-ion battery electrodes. By eliminating the need for solvents, it offers numerous environmental, economic, and safety benefits. However, the technology also presents unique challenges that require ongoing research and development to overcome. As advancements in materials, processes, and equipment continue, dry coating technology is poised to play a crucial role in the future of battery manufacturing, contributing to the production of high-performance, cost-effective, and environmentally friendly energy storage solutions.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com