Site de Blog

Linha de Máquinas de Fabricação de Células Cilíndricas Automáticas

fabricação e equipamento de laboratórios de bateria li-ion 18650

fluxograma de célula de moeda de íon de lítio e lista de máquinas

fabricação e equipamento de laboratórios de baterias com bateria de íon de lítio

dez 2016 aceitação de fábrica do cliente nos EUA da máquina de empilhamento automático

Contate-nos

- Se você tiver dúvidas, entre em contato conosco, todas as perguntas serão respondidas

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Adicionar : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produtos quentes

Prism battery is a form of lithium-ion battery, characterized by a hard metal or plastic outer shell and multiple layers of positive and negative plates and separators inside the battery.

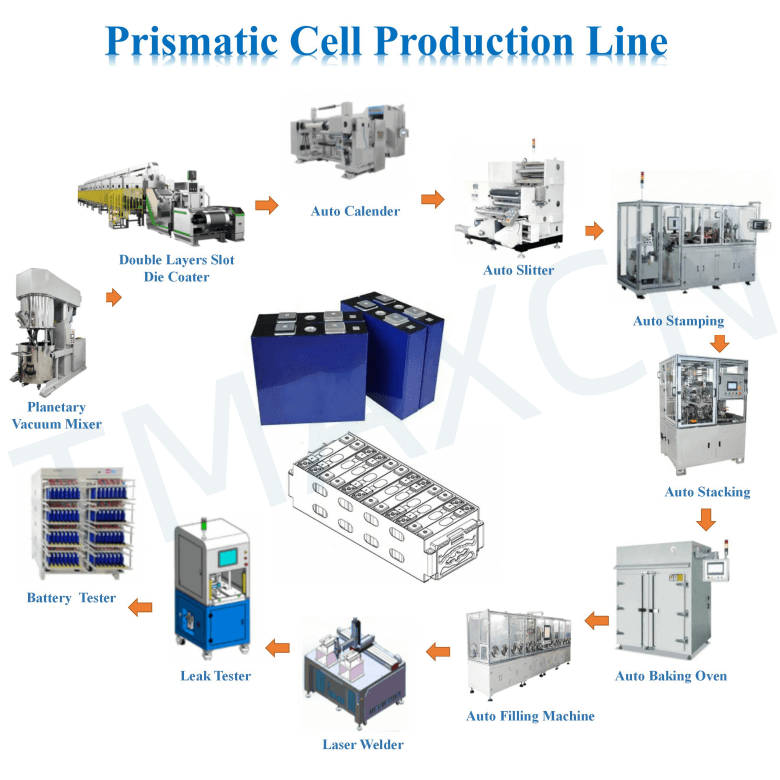

The production line of prism batteries mainly includes the following steps:

1.Electrode manufacturing. This step includes mixing, coating, compaction, slicing, cutting, and other processes, with the aim of mixing active materials, conductive agents, adhesives, etc. into a slurry, coating it on a metal collector, then compacting it into thin sheets, and cutting it into appropriate sizes.

2. Cell assembly. This step includes lamination, welding, liquid injection, sealing, and other processes, with the aim of stacking the positive and negative electrode plates and membranes together, welding the leads, injecting electrolyte, and then packaging them in a prism shaped shell.

3 Aging and testing. This step includes pre charging, aging, sorting and other processes, with the aim of cycling the charge and discharge of the cell, activating chemical reactions inside the cell, improving the performance and stability of the cell, and classifying and testing the cell.

The Prismatic Cell Manufacturing Line involves several mechanical equipment that plays a crucial role in the production process. The primary equipment includes:

1. Film applicator coater: It is used to coat electrodes with the necessary materials to increase their performance and capacity.

2. Electrode Slitting Machine: It is used to slit the electrodes and the separator into the requisite size for use in the cell.

3. Mixing Machine: It is used to mix the active materials (anode and cathode) with the binders and solvents to form a paste used for electrode coating.

4. Electrolyte Filling Machine: It is used to fill the electrolyte in the prismatic cell.

5. Lamination Machine: It is used to stack the electrodes, separator, and electrolyte layers to form a complete cell.

6. Welding Machine: It is used to weld the tabs and terminals onto the prismatic cell to create an electrical connection.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com