Site de Blog

Blog recente

Linha de Máquinas de Fabricação de Células Cilíndricas Automáticas

fabricação e equipamento de laboratórios de bateria li-ion 18650

fluxograma de célula de moeda de íon de lítio e lista de máquinas

fabricação e equipamento de laboratórios de baterias com bateria de íon de lítio

dez 2016 aceitação de fábrica do cliente nos EUA da máquina de empilhamento automático

Contate-nos

- Se você tiver dúvidas, entre em contato conosco, todas as perguntas serão respondidas

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Adicionar : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

produtos quentes

blogue

Pouch Cell Manufacturing line

Pouch Cell Manufacturing Line: The Future of Efficient Battery Production

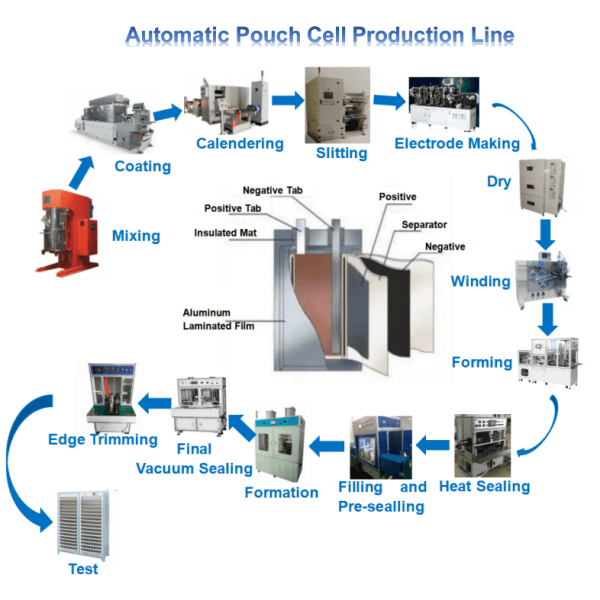

A pouch cell manufacturing line is a highly advanced, end-to-end system designed to automate and streamline the production of lithium-ion pouch cells. These lines integrate multiple stages of manufacturing, from raw material preparation to final testing, ensuring high-quality, consistent output while maximizing efficiency. In this blog post, we’ll explore what a pouch cell manufacturing line entails, its key components, how it works, and why it’s essential for modern battery manufacturing.

---

●What Is a Pouch Cell Manufacturing Line?

A pouch cell manufacturing line refers to a comprehensive production system that assembles lithium-ion batteries enclosed in flexible aluminum-plastic laminate pouches. It combines various machines and processes into a seamless workflow, enabling large-scale production with minimal human intervention. By automating critical steps like electrode preparation, stacking/winding, sealing, electrolyte injection, and quality testing, the manufacturing line ensures precision, consistency, and scalability in pouch cell production.

---

●Key Stages of a Pouch Cell Manufacturing Line

A typical pouch cell manufacturing line consists of several interconnected stages:

1. Material Preparation

- Cathode and Anode Slurry Mixing: Active materials (e.g., lithium cobalt oxide for cathodes, graphite for anodes) are mixed with binders and solvents to create slurries.

- Coating and Drying: The slurries are coated onto metal foils (aluminum for cathodes, copper for anodes) and dried to form electrodes.

- Cutting and Tab Welding: Electrodes are cut into precise dimensions, and current collector tabs are welded onto them.

2. Stacking/Winding

- Stacking: Electrodes and separators are layered sequentially to form a flat stack.

- Winding (optional): For jelly-roll configurations, electrodes and separators are wound together. While less common for pouch cells, some designs may use this method.

3. Pouch Insertion

- The electrode assembly is carefully placed inside a pre-cut aluminum-plastic laminate pouch.

4. Sealing

- Three sides of the pouch are sealed using heat sealing or ultrasonic welding to create an open enclosure for electrolyte injection.

5. Electrolyte Injection

- Liquid electrolyte is injected into the pouch through the open side to enable ion movement between electrodes.

6. Final Sealing

- The fourth side of the pouch is sealed to create an airtight enclosure, protecting internal components from external contaminants.

7. Formation and Activation

- Cells undergo formation cycles where they are charged and discharged under controlled conditions to activate their electrochemical properties.

8. Testing and Quality Control

- Rigorous tests are conducted to verify capacity, internal resistance, leakage, swelling, safety, and durability. Defective cells are discarded, while qualified cells proceed to packaging.

9. Packaging

- Finalized pouch cells are packaged for shipping or integration into consumer electronics, electric vehicles, or energy storage systems.

---

●Advantages of a Pouch Cell Manufacturing Line

1. High Throughput:

- Automation enables faster production rates, meeting the growing demand for pouch cells across industries.

2. Precision and Consistency:

- Advanced machinery ensures accurate alignment, stacking, and sealing, reducing defects and improving product uniformity.

3. Cost Efficiency:

- Reduces labor costs and minimizes material waste through precise handling and processing.

4. Scalability:

- Can be configured for small-scale prototyping or large-scale mass production, depending on the application.

5. Improved Safety:

- Minimizes human exposure to hazardous materials like electrolytes and ensures safer working conditions.

6. Customization:

- Modular designs allow manufacturers to adapt the manufacturing line for different cell sizes, chemistries, and applications.

Battery Production Line

●Challenges in Pouch Cell Manufacturing Lines

While pouch cell manufacturing lines offer numerous benefits, they also present certain challenges:

1. Complex Integration:

- Coordinating multiple machines and processes requires advanced engineering and software control systems.

2. Swelling Management:

- Managing pouch swelling during electrolyte injection and subsequent cycling remains a technical challenge.

3. Sealing Integrity:

- Ensuring reliable seals that withstand repeated charge-discharge cycles is critical but challenging.

4. Maintenance Requirements:

- Regular calibration and maintenance are necessary to maintain optimal performance and avoid downtime.

5. Material Handling:

- Handling delicate components like electrodes and separators without causing damage requires precise mechanisms.

---

●Innovations in Pouch Cell Manufacturing Lines

To address these challenges and enhance productivity, manufacturers are incorporating cutting-edge technologies into pouch cell manufacturing lines:

1. Advanced Sensors and Vision Systems:

- Real-time monitoring of electrode alignment, sealing quality, and electrolyte levels ensures consistent output.

2. AI and Machine Learning:

- Predictive analytics optimize machine performance, detect anomalies, and improve yield rates.

3. Modular Design:

- Flexible manufacturing lines can be easily reconfigured for different cell types and chemistries.

4. Sustainability Features:

- Eco-friendly designs minimize energy consumption and material waste during production.

5. Solid-State Integration:

- Future manufacturing lines will adapt to handle solid-state electrolytes, enabling safer and more efficient next-generation batteries.

6. Automated Quality Control:

- Advanced testing systems ensure every cell meets stringent quality standards before leaving the line.

---

●Applications of Pouch Cell Manufacturing Lines

Pouch cell manufacturing lines are widely used across industries requiring lightweight, high-energy-density batteries:

1. Consumer Electronics

- Smartphones, tablets, laptops, and wearables benefit from the compact and customizable nature of pouch cells.

2. Electric Vehicles (EVs)

- Many EV manufacturers rely on pouch cells for their superior energy density and space optimization.

3. Energy Storage Systems

- Residential and commercial energy storage solutions increasingly adopt pouch cells for scalability and efficiency.

4. Aerospace and Defense

- Lightweight pouch cells power drones, satellites, and other aerospace applications demanding high-performance energy storage.

---

●The Future of Pouch Cell Manufacturing Lines

As the demand for advanced batteries grows, pouch cell manufacturing lines will continue to evolve. Key trends shaping the future include:

1. Higher Throughput:

- Advances in automation and robotics will further boost production speeds without compromising quality.

2. Customization Options:

- Modular designs will allow manufacturers to tailor manufacturing lines for specific cell types and chemistries.

3. Sustainable Manufacturing:

- Recycling capabilities and eco-friendly processes will become integral parts of future manufacturing lines.

4. Integration with Emerging Technologies:

- Solid-state batteries, flexible electronics, and autonomous systems will drive new innovations in pouch cell manufacturing.

5. Smart Factories:

- Fully connected smart factories will leverage IoT, AI, and big data to optimize production, reduce waste, and enhance efficiency.

---

●Conclusion

Pouch cell manufacturing lines are indispensable tools in modern battery manufacturing, driving innovation and efficiency in the production of lightweight, high-performance pouch cells. As advancements in materials science, automation, and sustainability continue to unfold, these manufacturing lines will play an increasingly important role in shaping the future of energy storage.

April 25,2025.

Pouch Cell Manufacturing Line: The Future of Efficient Battery Production

A pouch cell manufacturing line is a highly advanced, end-to-end system designed to automate and streamline the production of lithium-ion pouch cells. These lines integrate multiple stages of manufacturing, from raw material preparation to final testing, ensuring high-quality, consistent output while maximizing efficiency. In this blog post, we’ll explore what a pouch cell manufacturing line entails, its key components, how it works, and why it’s essential for modern battery manufacturing.

---

●What Is a Pouch Cell Manufacturing Line?

A pouch cell manufacturing line refers to a comprehensive production system that assembles lithium-ion batteries enclosed in flexible aluminum-plastic laminate pouches. It combines various machines and processes into a seamless workflow, enabling large-scale production with minimal human intervention. By automating critical steps like electrode preparation, stacking/winding, sealing, electrolyte injection, and quality testing, the manufacturing line ensures precision, consistency, and scalability in pouch cell production.

---

●Key Stages of a Pouch Cell Manufacturing Line

A typical pouch cell manufacturing line consists of several interconnected stages:

1. Material Preparation

- Cathode and Anode Slurry Mixing: Active materials (e.g., lithium cobalt oxide for cathodes, graphite for anodes) are mixed with binders and solvents to create slurries.

- Coating and Drying: The slurries are coated onto metal foils (aluminum for cathodes, copper for anodes) and dried to form electrodes.

- Cutting and Tab Welding: Electrodes are cut into precise dimensions, and current collector tabs are welded onto them.

2. Stacking/Winding

- Stacking: Electrodes and separators are layered sequentially to form a flat stack.

- Winding (optional): For jelly-roll configurations, electrodes and separators are wound together. While less common for pouch cells, some designs may use this method.

3. Pouch Insertion

- The electrode assembly is carefully placed inside a pre-cut aluminum-plastic laminate pouch.

4. Sealing

- Three sides of the pouch are sealed using heat sealing or ultrasonic welding to create an open enclosure for electrolyte injection.

5. Electrolyte Injection

- Liquid electrolyte is injected into the pouch through the open side to enable ion movement between electrodes.

6. Final Sealing

- The fourth side of the pouch is sealed to create an airtight enclosure, protecting internal components from external contaminants.

7. Formation and Activation

- Cells undergo formation cycles where they are charged and discharged under controlled conditions to activate their electrochemical properties.

8. Testing and Quality Control

- Rigorous tests are conducted to verify capacity, internal resistance, leakage, swelling, safety, and durability. Defective cells are discarded, while qualified cells proceed to packaging.

9. Packaging

- Finalized pouch cells are packaged for shipping or integration into consumer electronics, electric vehicles, or energy storage systems.

---

●Advantages of a Pouch Cell Manufacturing Line

1. High Throughput:

- Automation enables faster production rates, meeting the growing demand for pouch cells across industries.

2. Precision and Consistency:

- Advanced machinery ensures accurate alignment, stacking, and sealing, reducing defects and improving product uniformity.

3. Cost Efficiency:

- Reduces labor costs and minimizes material waste through precise handling and processing.

4. Scalability:

- Can be configured for small-scale prototyping or large-scale mass production, depending on the application.

5. Improved Safety:

- Minimizes human exposure to hazardous materials like electrolytes and ensures safer working conditions.

6. Customization:

- Modular designs allow manufacturers to adapt the manufacturing line for different cell sizes, chemistries, and applications.

Battery Production Line

●Challenges in Pouch Cell Manufacturing Lines

While pouch cell manufacturing lines offer numerous benefits, they also present certain challenges:

1. Complex Integration:

- Coordinating multiple machines and processes requires advanced engineering and software control systems.

2. Swelling Management:

- Managing pouch swelling during electrolyte injection and subsequent cycling remains a technical challenge.

3. Sealing Integrity:

- Ensuring reliable seals that withstand repeated charge-discharge cycles is critical but challenging.

4. Maintenance Requirements:

- Regular calibration and maintenance are necessary to maintain optimal performance and avoid downtime.

5. Material Handling:

- Handling delicate components like electrodes and separators without causing damage requires precise mechanisms.

---

●Innovations in Pouch Cell Manufacturing Lines

To address these challenges and enhance productivity, manufacturers are incorporating cutting-edge technologies into pouch cell manufacturing lines:

1. Advanced Sensors and Vision Systems:

- Real-time monitoring of electrode alignment, sealing quality, and electrolyte levels ensures consistent output.

2. AI and Machine Learning:

- Predictive analytics optimize machine performance, detect anomalies, and improve yield rates.

3. Modular Design:

- Flexible manufacturing lines can be easily reconfigured for different cell types and chemistries.

4. Sustainability Features:

- Eco-friendly designs minimize energy consumption and material waste during production.

5. Solid-State Integration:

- Future manufacturing lines will adapt to handle solid-state electrolytes, enabling safer and more efficient next-generation batteries.

6. Automated Quality Control:

- Advanced testing systems ensure every cell meets stringent quality standards before leaving the line.

---

●Applications of Pouch Cell Manufacturing Lines

Pouch cell manufacturing lines are widely used across industries requiring lightweight, high-energy-density batteries:

1. Consumer Electronics

- Smartphones, tablets, laptops, and wearables benefit from the compact and customizable nature of pouch cells.

2. Electric Vehicles (EVs)

- Many EV manufacturers rely on pouch cells for their superior energy density and space optimization.

3. Energy Storage Systems

- Residential and commercial energy storage solutions increasingly adopt pouch cells for scalability and efficiency.

4. Aerospace and Defense

- Lightweight pouch cells power drones, satellites, and other aerospace applications demanding high-performance energy storage.

---

●The Future of Pouch Cell Manufacturing Lines

As the demand for advanced batteries grows, pouch cell manufacturing lines will continue to evolve. Key trends shaping the future include:

1. Higher Throughput:

- Advances in automation and robotics will further boost production speeds without compromising quality.

2. Customization Options:

- Modular designs will allow manufacturers to tailor manufacturing lines for specific cell types and chemistries.

3. Sustainable Manufacturing:

- Recycling capabilities and eco-friendly processes will become integral parts of future manufacturing lines.

4. Integration with Emerging Technologies:

- Solid-state batteries, flexible electronics, and autonomous systems will drive new innovations in pouch cell manufacturing.

5. Smart Factories:

- Fully connected smart factories will leverage IoT, AI, and big data to optimize production, reduce waste, and enhance efficiency.

---

●Conclusion

Pouch cell manufacturing lines are indispensable tools in modern battery manufacturing, driving innovation and efficiency in the production of lightweight, high-performance pouch cells. As advancements in materials science, automation, and sustainability continue to unfold, these manufacturing lines will play an increasingly important role in shaping the future of energy storage.

What excites you most about the future of pouch cell manufacturing lines? Share your thoughts in the comments below! Together, let’s explore how technology can drive a cleaner, more sustainable energy landscape.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com